After seeing some posts on engine bay lighting I installed the TEQ Off-road under hood lighting today. I’m amazed that the “generic” version (TEQ is a Yoda shop) fits perfectly.

It’s not the cheapest option ( compared to Amazon 12” strip kits), but it’s currently $55 instead of the suggested $115 price from TEQ.

It comes with a 40” LED strip that provides plenty of light, shielded cable harness, inline fuse, a negative switched plunger and override button switch. Also includes plenty of cable management bits to tidy up the install. The finer points, the amount of light it throws and the perfect fit make it good value IMO.

I centered the strip on the hood in the only logical place it will go. It adhered nicely, but I had to leave a couple of gaps to conform to the under hood contours. I popped a two of the big plug clips using a panel tool on the insulation and routed the cable under the installation. The clips took a little coaxing to get out but went back in firmly.

Routed the wiring “harness” along some existing cables on the drivers side. The positive connected to the battery with just the right amount of slack, nothing extra.

I chose to drill a hole in the battery hold down bracket to mount the plunger switch. And again just the right amount of cable to be able to reasonably attach the spade connection, but nothing more. I mounted the switch to the inside of the fender well using the provided doubled sided tape. Used a few of their cable ties to secure everything, but there really wasn’t any excess cable flopping around.

Took a couple tries to get the plunger set to the right height, but it was easy enough with a couple 12mm wrenches.

Overall install was about 30 minutes taking my time to make sure the harness routed nicely.

Lights up well and evenly.

View attachment 15462

You can see the override button switch on the fender behind ground and the plunger switch mount here.

View attachment 15463

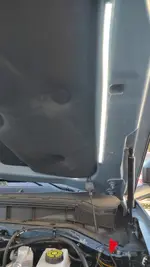

Cable exiting the hood insulation

View attachment 15464

Cable entering hood insulation and the light strip.

View attachment 15465